Written By Emily Pesina

Aspiring, stylish, and essential一the fashion departments at Austin Community College have cultivated Austin once again. From bringing awareness to heart health with the Red Dress campaign, to an expected Corset-making for Breast Cancer Awareness, this year’s big project: to create COVID masks for essential employees who continue to work on campus. ACCENT sat down with the working riverbats who were there that day to reminisce over their experience with the face cloth that was to be produced, times a thousand.

When the ACC district closed its doors due to the pandemic, Victoria Taylor, professor and head chairperson for the fashion and design department at ACC, immediately reached out to campus operations. “When this pandemic started, I was reaching out right away to my dean and my vice president saying ‘we have fabric, I have stitchers [and] students who can make masks. How can we help?”” said Taylor. It turned out that the head of campus operations, Sharrion Jenkins, had the same idea. Both women, having worked together before with their knowledge in the fashion lab and its equipment, were connected in thought when this idea was emerging. Taylor and Jenkins put their resources together. The space and equipment was already there, now all that was needed were working hands for the project.

“The way the project came along was, it had to do with the need. We could not find masks when it became apparent that COVID had hit the U.S… being in operations, we were responsible for the COVID response”, said Jenkins. At the start of the project, Taylor juggled the needles of meeting her students’ needs and being available for the mask-making project, and Jenkins faced a shortage of thread. However, supply of thread was found in the most unlikely places, which was necessary in order to produce quality masks. With the fabrics already there, which were provided by donations from the fashion and design department, the mannequins were set aside and social distancing guidelines were put in place to create a safe and working environment. Once the facility support, under Jenkin’s wing, clashed in the working space, then it was time to get started.

“Even though it was stressful because we didn’t really know what was going on with this virus, we felt like we were doing our part”, says Jenkins. Sitting a machine apart and working one person at a table, she noted that her workers kept a positive attitude in this. Jenkins explains that many of the workers knew how to legitimately sew, and everyone was excited about this project because they got to do different things rather than the same procedures everyday, which made the experience not monotonous at all.

With the working women sewing inside, other employees, notably the campus managers across the district, wanted to help. Packs to make ten masks were placed inside a plastic bag with all the pieces included, and were safely distributed to helpers who would come pick it up. They would then take it home to sew all the pieces together, and bring it back to campus once all the pieces were joined together. “Everybody was amazed at the end… there was never a time when we said we couldn’t do it”, mentioned Jenkins. Summing up the experience as “fun” and “togetherness”, she mentions that even though nobody knew how the project would end up, the initial goal of one-hundred masks, which then turned into five hundred masks, became a long and hardworking thousand for essential employees who continue to work on campus today.

For Victoria Taylor, she sums up her experience assisting with the masks as “proud”. Taylor pushes her students to not only keep your focus on what’s on your desk, but extend your vision

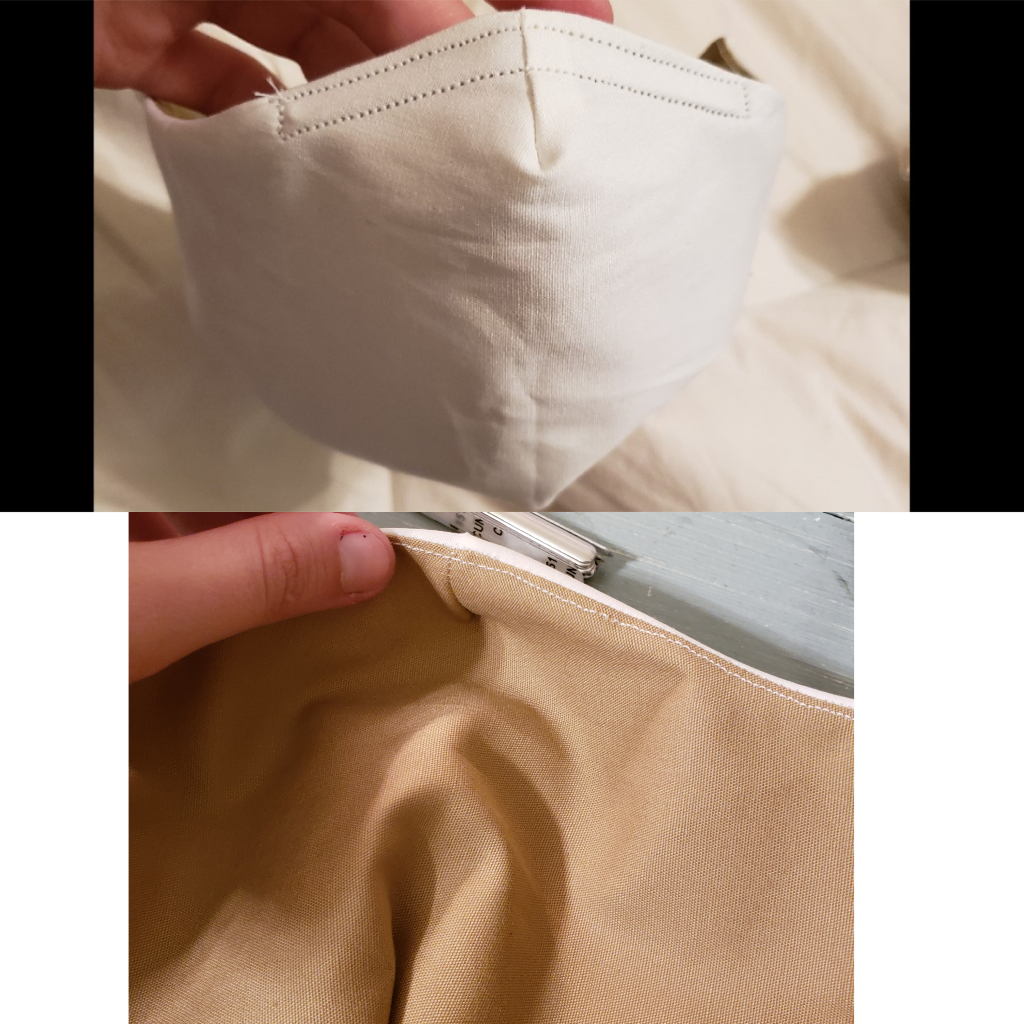

into the world to be aware of what’s going on, and how you can give back to the community. That is the oath that student Isabella Collins went through. Collins, a second-year Fashion Design student and employed by the Fashion Incubator, has aspiring ambitions to start her own brand. After being left jobless for several months since she had quit her salesperson job to fulfill an internship that would be interrupted by COVID, Collins was called in for a project that involved lots and lots of facemasks. Having prior experience in crafting and selling masks on the side as a means to make some cash, becoming part of the Fashion Incubator’s thousand-mask creation一a separate project than the Fashion & Design’s department一threw Collins into a cycle of sewing, mistakes, frustration, ripping seams, starting over, sticky needles, and surprises that put her skills, equipment, and patience to the test. Fortunately, her understanding boss allowed her to produce masks on site at the Fashion Incubator, which was a real improvement as far as her progress.

“I’m a very determined person,” says Collins, “but I do get frustrated doing the same thing every day, so it definitely taught me to stick with it and to have self-control… even when you’re good at something, mistakes still happen.” After being able to transition from working at home to on site, her new durable equipment that could produce masks much faster still posed challenges to her and her team. Her mental and physical health, as well as her schedule, were put to the test. Yet she was able to stick to a schedule that allowed her to balance her schoolwork and her job. Keeping herself motivated through exercise and her teammates, the stress that the team felt was worked through to meet their daily goals, which in turn became a three month project with a thousand and one masks produced.

With unique materials to create this two-color sided mask, Collins says that even though it was mentally challenging, the experience in working with the Fashion Incubator to create its own thousand-mask creation definitely toughened her up, which is why she sums up her experience working in the fashion incubator as “perseverance.” After months spent producing the same mask, Collins is grateful to have been part of this project and challenge, as she calls on others to take similar steps. “Take opportunities that may not be what they seem. You can learn so much from jobs that you don’t expect will help you… me getting a window sales job, that does not seem like a job that a designer would want, but I learned so much about the process…” Collins believes that every opportunity and job that you go through can benefit you in some way. “Don’t look down on yourself because you can’t get that high end job, because everything you go through will help you later on.” Life is a teacher and we are its students embarking on our own journey.

Visit the ACC Fashion Design Website for more details about the area of study.